Becker’s Sub-Assembly Services: Streamlining Production & Reducing Costs

Becker’s Sub-Assembly Services: Streamlining Production & Reducing Costs

Why Outsource Sub-Assembly?

For many industrial operations, time, space, and manpower are valuable resources. Building sub-assemblies in-house often leads to bottlenecks, wasted labor, and higher costs—especially for companies trying to scale production.

That’s why Becker Engineered Systems provides comprehensive sub-assembly services. These allow businesses to focus on core production while reducing overhead, increasing efficiency, and improving turnaround times.

“Outsourcing sub-assemblies frees up production space and optimizes workforce utilization,” says Bryan Jostworth, Vice President of Business Development at Becker Engineered Systems. “Our customers no longer have to tie up capital, inventory, or key personnel for assembly work—we handle it all.”

🔹 The Challenges of In-House Sub-Assembly

⚠ Production Space Constraints – Assemblies take up valuable floor space that could be used for higher-value operations

⚠ Labor Allocation Issues – Skilled workers spend time on repetitive sub-assembly tasks instead of core production

⚠ Inventory & Supply Chain Complexity – Managing parts, storage, and logistics internally can be overwhelming

⚠ Longer Lead Times – In-house sub-assembly delays final product completion

🔹 How Becker’s Sub-Assembly Services Improve Production

🔥 Key Benefits:

✅ Faster Production & Delivery

📌 Pre-assembled components mean quicker installation & shorter lead times

✅ Lower Fixed Costs & Overhead

📌 Eliminate the need for extra warehouse space, inventory management, and labor allocation

✅ Scalable & Customizable Solutions

📌 We assemble mechanical, electrical, and automation components to your exact specifications

✅ Integrated Quality Control

📌 Every sub-assembly undergoes rigorous testing before delivery to ensure reliability

📌 Learn More About Becker’s Sub-Assembly Services ➝ https://www.beckerengineeredsystems.com/services/sub-assembly-services

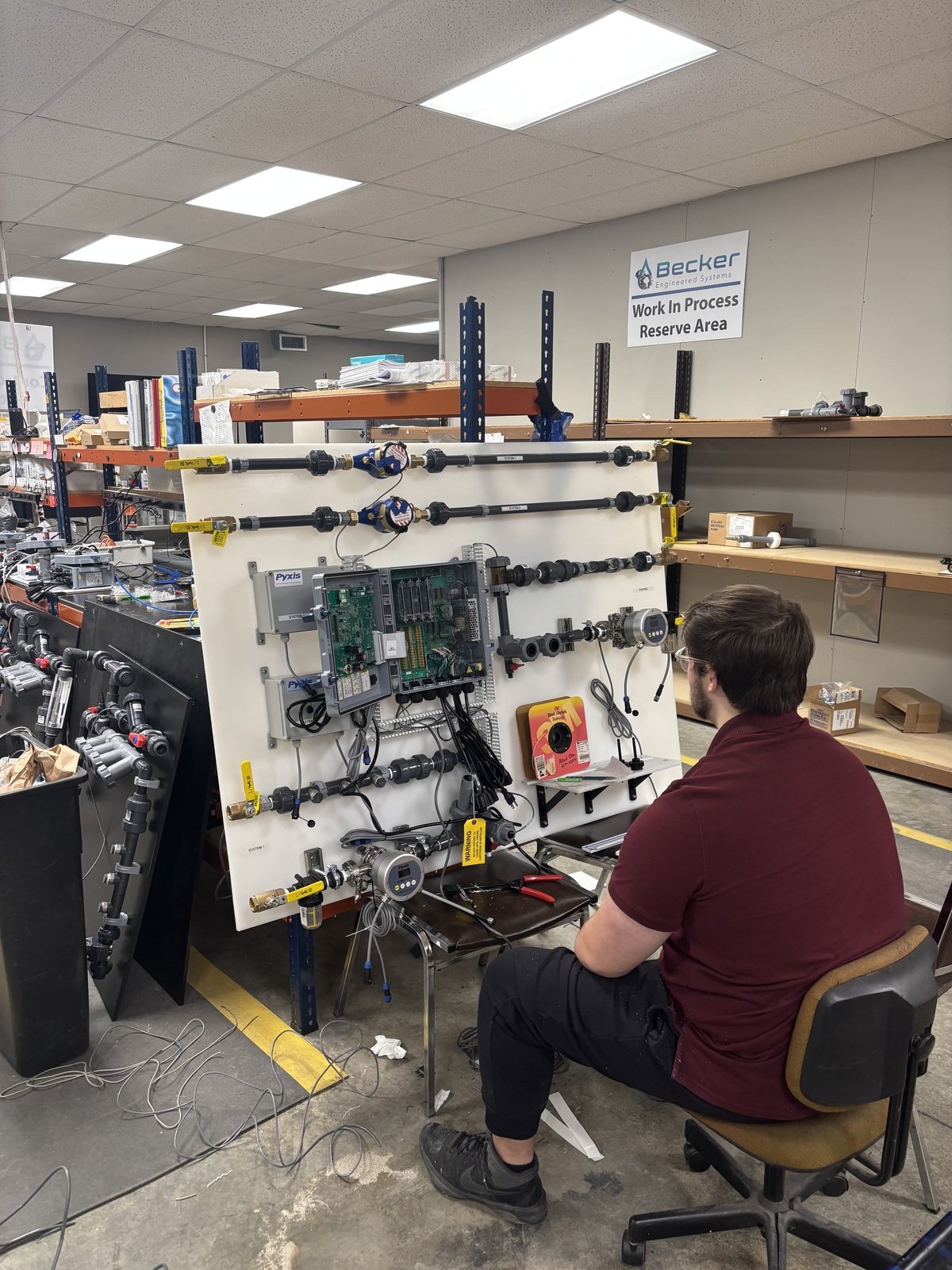

🔹 What We Assemble at Becker

✔ Mechanical & Fluid System Sub-Assemblies

📌 Includes pump assemblies, skid-mounted fluid-handling systems, and filtration modules

✔ Electrical & Control Panel Sub-Assemblies

📌 Pre-wired control panels & automation enclosures for easy installation

✔ Modular Dosing & Chemical Feed Systems

📌 Custom chemical dosing skids & metering pump assemblies

✔ HVAC & Industrial Process Components

📌 Fully assembled actuators, valves, and sensor kits

📌 See Becker’s Custom Assembly Capabilities ➝ https://www.beckerengineeredsystems.com/industries

“We assemble and test every component before shipping,” says Greg Tankersley, President of Becker Engineered Systems. “Customers receive ready-to-install solutions that reduce installation time and increase efficiency.”

🔹 Industries That Benefit from Becker’s Sub-Assembly Services

✔ OEMs & Manufacturing – Prefabricated components for quick assembly into larger systems

✔ Water & Wastewater Treatment – Skid-mounted chemical feed & filtration systems

✔ HVAC & Building Automation – Fully assembled actuators & control panels

✔ Chemical Processing & Industrial Facilities – Pre-tested pump & dosing assemblies

✔ Food & Beverage Processing – Pre-assembled hygienic systems for compliance

📌 See Becker’s Industry-Specific Solutions ➝ https://www.beckerengineeredsystems.com/industries

🔹 Why Choose Becker for Sub-Assembly?

✔ Reduced Lead Times & Faster Installations – Eliminates in-house assembly bottlenecks

✔ Cost Savings on Labor & Inventory Management – Lower fixed costs & better resource allocation

✔ High-Quality, Pre-Tested Components – Ensures reliability & performance before installation

✔ Custom-Engineered for Your Application – Designed to match your exact process requirements

📌 Speak to an Expert About Becker’s Sub-Assembly Solutions ➝ https://www.beckerengineeredsystems.com/contact-us

📧 Have Questions? Contact Us Today!

📞 Call: (513) 874-3372

📧 Email: info@beckerengineered.com

🌐 Visit: www.beckerengineeredsystems.com

Let’s do the Sub-Assembly for you today! 🚀