Iwaki America Pumps & Equipment Designs

🔹 Iwaki at Becker Engineered Systems – In Stock & Ready to Ship

Range of Iwaki America Pumps: Leaders in Chemical Handling Equipment

🔹 Iwaki at Becker Engineered Systems – In Stock & Ready to Ship

Becker Engineered Systems is pleased to offer the full Iwaki America Mag Dive and AODD pumps.

Becker covers Southern Ohio, Indiana, Kentucky, and West Virginia. Since 2012, it has been a gold-level distributor of Iwaki America’s Walchem water treatment controllers, sensors, and pumps.

Contact one of our application professionals for the pump specification that meets your needs. Contact Us

Becker Smart System Integration

🛠 Upgrade with Becker Connected Systems

Iwaki’s precision pumps seamlessly integrate with Becker Connected Systems, enabling:

✅ Real-time performance monitoring.

✅ AI-driven predictive maintenance alerts.

✅ Seamless SCADA & PLC compatibility for industrial automation.

📌 Learn About Smart System Integration

Why Buy Iwaki from Becker?

✅ Fastest Shipping in the Industry – In stock & ready to ship.

✅ Expert Technical Support – Our engineers help with setup & integration.

✅ Custom Solutions Available – Need a custom-built system? We can configure it for you.

Leading the Industry Worldwide with Over 60 Years of Pump Design Engineering

The best chemical handling equipment:

Iwaki America Inc. is one of over 25 global centers for the manufacturing and support of Iwaki pumps. Their 60-plus years of pump design engineering have made them a worldwide leader in the best chemical handling equipment used in OEM, Industrial, Chemical Process, and Semiconductor applications. Iwaki America, along with Iwaki Air and Walchem, shares a state-of-the-art manufacturing facility in Holliston, Massachusetts. Located 30 miles southwest of Boston, Iwaki America, Inc. and Walchem are strengthened by sharing combined administration and corporate management resources, yet each company maintains and focuses on its own research and development, sales, customer service, and manufacturing. Their modern facilities provide enhanced communications between all departments and allow for enthusiastic and productive employees, many of whom have been with the company for decades. They utilize the best data management techniques to serve customers in the excellent manner they have come to expect.

Excellence in Quality and Durability: Iwaki America's Commitment

Rigorous Quality Control

Their chemical pumps are favored the world over and our range of products have been developed for increasingly diverse applications. Their products meet strict quality criteria. Based on cell production methods, the entire flow from assembly to packaging is done at the same workstations. Rigorous inspections are done at every process stage using the latest test equipment and ISO9001 based quality control standards. Moreover, based on their integrated internal standards, they strive to achieve zero defect rates. Since the entire production flow from assembly to packaging is done at the same workstations, they have successfully improved their quality and productivity, making it possible to offer fluid control equipment having excellent durability. In addition to their high-quality standards, they supply products that minimize ownership costs for our customers.

Powerful Performance and Versatility with Iwaki America Pumps

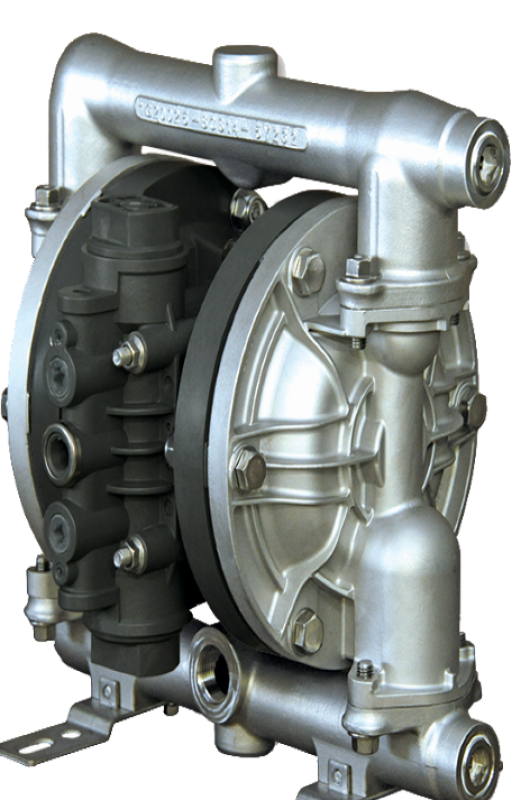

Iwaki America also offers a wide range of industrial air-operated double diaphragm pumps and high-purity pumps. Iwaki Air AODD pumps are engineered for maximum utility. They are portable and easy to install, operate, and maintain. Infinitely variable flow rates and variable discharge pressures can handle a large range of fluids, including corrosive chemicals and flammable liquids. Iwaki Air AODD pumps can run dry, self-prime, and dead-head without damaging the pump. Other design elements that distinguish Iwaki Air AODD pumps include body stabilization features to ensure heat resistance, and sound suppression construction to reduce both mechanical noise and compressed air noise. Most important, the lube-free air valve features a non-centering spring specially designed not to stall and is accessible for easy maintenance.

These pumps are built for power. A higher power output means the pump can operate with less applied air pressure compared with many competitor pumps – often outperforming pumps that may have a higher listed flow rate.

- Chemical Manufacturing

- Chemical Toting + Packaging

- Chemical Blending

- Water Treatment

- Plating

- Metal Finishing

- Metal Pickling

- Battery Manufacturing

- Mining

- Bio-Fuels

- Desalination

- Paper Mill

- Refineries

- Semiconductor

- + More!